On the Way to the Alpha Version of the Hydroptics Platform

Andreas Genner, Dirk Askamp, Stella Schmode, Wolfgang Ritter

QuantaRed Technologies GmbH

Making the oil and gas industry more environmentally friendly is a major concern nowadays. Optimizing the involved process streams is crucial to achieve this goal. Different approaches are available to improve the productivity and sustainability. Within the European project Hydroptics it was chosen to solve these challenges utilizing advanced process modelling and by stepping up the analytical information available for the involved streams.

During the last months, the members of the Hydroptics consortium have taken a significant effort to improve measurement techniques, to develop new hardware and to evaluate innovative measurement setups. As the focus of this European project lies in optimizing the handling of produced water that origins from the oil and gas industry, it has been decided to take particle sensing and the quantification of hydrocarbons in water to the next level of process monitoring. Therefore, suitable hardware has been developed and the individual components will be integrated into the alpha version of the Hydroptics platform very soon.

Each project partner contributes their experience and knowledge to build the components, that will lead to the first generation of the Hydroptics platform. These are, in particular:

-

A Hyperspectral Imaging setup, that will enable differentiating the material of the particles,

-

A fluorescence module, that will allow to determine the size of oil droplets,

-

An infrared setup, which is based on state-of-the-art Dual Frequency Combs,

-

And a QCL-based module, allowing sensitive Oil-in-Water measurements.

To deliver precise and correct measurement values, additional sample preparation and ancillary tools are required. This will be achieved by installing ultrasound technology to guide the particles for high-resolution imaging and advanced liquid/liquid extraction, that will allow precise Oil-in-Water measurements. A customized separator, is planned for the second iteration of the Hydroptics platform. It will enable continuous monitoring of the Oil-in-Water content and reduce the risk of clogged filters.

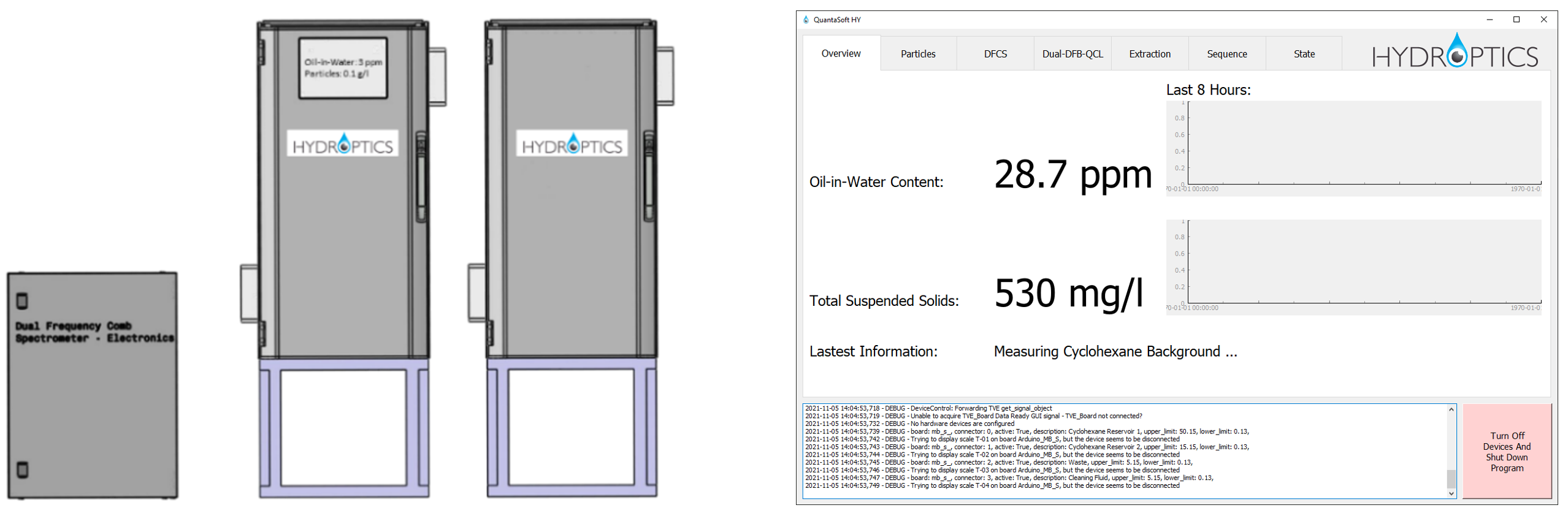

Aside precise and correct results, the industry requires a robust and spray water resistant enclosure. Therefore, the individual hardware modules will be installed in a housing can easily be adopted to individual needs within the Hydroptics project.

As it is planned to evaluate the Hydroptics platform under lab conditions and later in the field as well, the transportability of the measurement unit is crucial. This is guaranteed by equipping the housing with wheels, allowing experiments at different sampling points at different locations in a refinery or water treatment plant.

An important item related to user friendliness is the software interface. The alpha version of the Hydroptics platform will feature an easy-to-use touch-screen display. While for the first step of the integration of Hydroptics a reduced number of devices will be controllable, the beta version will allow the user to interact with all installed measurement techniques. As on-line sensors are often monitored from process control centers, the Hydroptics platform will also provide full software remote access, as well as typical interfaces to process control systems.

With the assembly of all sub-modules and the alpha version of the Hydroptics platform going on, stay tuned for the next update on Hydroptics!

Link: https://hydroptics.eu/wp-content/uploads/2021/11/Press_release_5.pdf