The EU is the second largest producer of petroleum products in the world after the United States, with a crude refining capacity of about 15 million barrels per day, representing 16% of total global capacity.

Technology for oil production needs to be constantly refined and improved for competitive oil production in Europe as well as by European companies overseas. In both up- and down stream processing, water is of crucial importance.

Often it is the water quality that has a decisive effect on the overall efficiency of upstream operations in Europe as well as in downstream oil processing. Therefore, having a reliable, cost-effective, and high-accuracy monitoring of produced water quality is of utmost importance for oil industry.

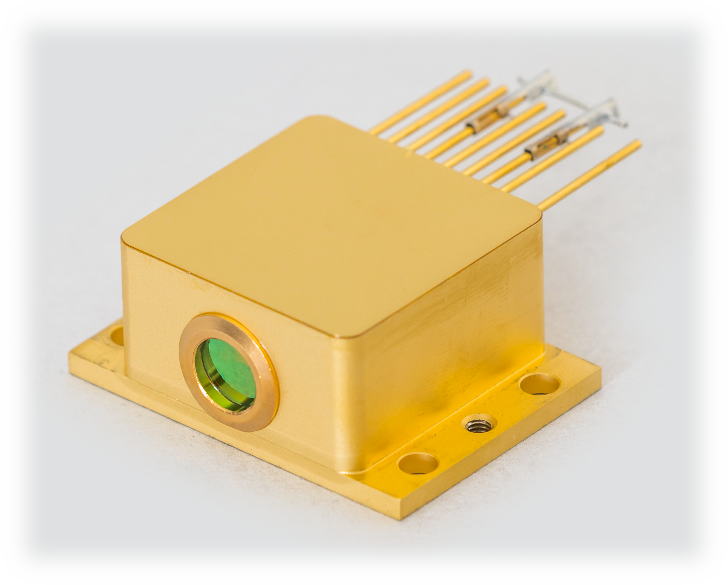

HYDROPTICS will develop and apply advanced photonic components as key enabling technologies for optimizing most critical steps in oil production as well as to control downstream processing routines for final mineral oil product development.

In this regard process water has been identified as a key product of high relevance both in upstream and downstream process monitoring. It will also elaborate how data provided by these advanced sensors can be combined with readily available process data, and a digital twin of the process apparatus to gain in-depth process understanding.

Digitalisation of process data, data fusion, machine learning and artificial intelligence shall enable a new level of process optimization yielding high and constant product quality despite fluctuating process conditions. In particular, HYDROPTICS technological objectives are:

Technological impact

The developments in HYDROPTICS will cover the entire value chain from laser source R&D towards a laser based spectrometer towards online and inline subsystems for oil in water monitoring. All of these modules and sub-systems and systems are exploitable separately. For the partners this will lead to leadership positions in the supply of fast QCL frequency comb lasers and spectrometers, online and inline oil in water analysers.

The ban of ozone-depleting CFS opened the market window for a new type of highly sensitive infrared spectroscopy technology. With the technology comes a realistic chance to substitute CFC-based systems and reach leadership in dedicated markets of oil in water analysis. The generic technology will widen the scope to numerous online and inline water monitoring applications (e.g. problems of eutrophication).

Furthermore, via the adoption data-assimilation and digital twins, HYDROPTICS aims to drive the EU oil industry towards a new, more advanced and digitised era.

HYDROPTICS is based on careful selection of project partners with complementary innovation capacities. The project will reinforce the already established cooperation between ALPEs, IMEC, QRT, IRSWEEP, TUW and OMV, all partners within several current Horizon 2020 & Eurostars projects. Beyond that, the consortium has been extended towards the end-user side demonstrating the strong industrial commitment The consortium members of HYDROPTICS cover the whole value and supply chain from academia (TUW), device providers and component manufacturers (ALPES, IMEC) to the systems integrator / systems vendor (QRT, SAL, IRSWEEP) and the bridge- and end-users (OMV, TUPRAS, DBC).

The HYDROPTICS activities will build on the pilot line activities of EC project MIRPHAB, where ALPES, IMEC and QRT are members, and where IRSWEEP has been selected in the open call programme. The online and inline systems will be integrated by QRT with the support of module integrators IMEC, and ALPES. Scientific support with respect to measurement strategies and support during product development will be provided by TUW, innovation support comes from DBC. The online OiW analyser will be validated within HYDROPTICS with partners OMV and TUPRAS in real settings of the oil industry.

Environmental impact

Environmental impact of industrial activity remains one of the biggest structural challenges facing the EU today. The way we grow, produce and import goods contributes substantially to climate change, and directly affects our lifestyle and overall quality of life. Even more so, in cases of highly industrialised countries, or in regions of close proximity to industrial activity.

A key inhibitor in further expanding oil extraction and processing in the EU, is the social pressure by citizens that oppose the construction of new oil extraction & refinery plants. Water purification can be seen as environ- mental water monitoring on the upstream side.

The water monitoring there includes all measures to avoid or early detect serious contamination of water resources. This encloses spill tracking (e.g. Deepwater Horizon, hydraulic fracturing), surface water control and monitoring of transportation induced contamination. The current standard for checking of hazardous contaminants is based on manual sampling and subsequently off-line analysis by a certified analytical laboratory.

Thus, the capability to be delivered by HYDROPTICS to carry out frequent online or continuous inline measurements constitutes a substantially improved sensing solution. Furthermore, the HYDROPTICS system can be part of an early-warning system for accidental or deliberate contaminations.

Hydroptics aims to put the sustainable oil production & processing on the EU agenda and for this we will consider in our impact plan the role standardisation can play and also to show that healthy HYDROPTICS could improve environmental sustainability.

The work plan has been structured in such a way, as to achieve quick delivery of the first results and allow a gradual validation of the approach for each component, leading to an overall validation of the HYDROPTICS platform.

WP overlapping has been planned in order to avoid delays in case of a single task being delayed due to unforeseen reasons. WP interconnection is shown in the Figure below. WP1, WP2, WP9 and WP10 are umbrella work packages, running in parallel with all activities throughout the project. WP3 is the first technical work package and provides input to the main technical WPs (WP4-5-6). Those three WPs are responsible for delivering all HYDROPTICS platform components modules. These modules are used as an input to WP7, which will deliver the integrated HYDROPTICS device.

Finally, the final, integrated and lab tested version of the HYDROPTICS device is used for the field validations in real industry settings, in WP8.

is the management work package. This is an umbrella WP, running throughout the project’s lifetime.

deals with all legal, GDPR, ethics, regulatory and certification/standardisation aspects of the project. This too, is an umbrella WP, running throughout the project’s lifetime.

deals with the preparation of the system requirements and with its conceptual design. Current practices, user needs and installation site details will be collected and analysed. This WP sets also the evaluation metrics for the system at a preliminary level. All requirements are used to prepare the preliminary, conceptual design of the HYDROPTICS system. Finally, the system technical specifications will be delivered through this WP.

deals with development and integration of the frequency comb & DFB Quantum Cascade Laser systems.

deals with development of Ancillary sensing components & methods development, based on WP3 input.

deals with development of algorithm regarding signal acquisition, processing & industrial process optimisation.

deals with developing the interfacing between subsystems, and interaction between the HYDROPTICS sensor platform and existing infrastructure at oil processing plants. It also tackles integration of all ICT components into a unified platform. Initial laboratory demonstration of the device prototype will be done in this WP.

is responsible for the device validation activities, in real industry settings. The device performance will be fully validated through this WP through comparisons with the golden standards systems. An impact assessment and usability analysis report for the device will also be here prepared.

is the Dissemination and Exploitation work package, which is also an umbrella WP running throughout project lifetime. A dissemination and exploitation plan will be delivered in M6 and will be updated every six months, Dissemination of results is obviously more active during the second half of the project, where the approach will be tested and validated. Results exploitation and patenting are also dealt through this WP.

deals with post-grant requirements on the data protection policy for personal data.