Online oil-in-water detection using dual-QCL spectroscopy

Background:

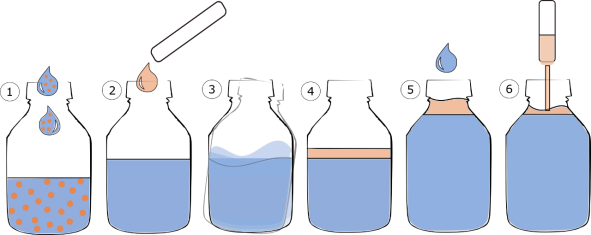

Industry proven methods for the reliable quantification of oil in water are generally based on absorption measurements. One such method (ASTM D7678) has been standardized by QuantaRed Technologies and employs a conventional extraction method using cyclohexane. (1) A defined amount of water (containing traces of oil) is sampled using an empty bottle, to which cyclohexane is added (2). The liquids are mixed (3) whereby all the oil is extracted into the cyclohexane phase. After phase separation (4), clean water is added (5) to allow for easy withdrawal of the enriched cyclohexane phase (6).

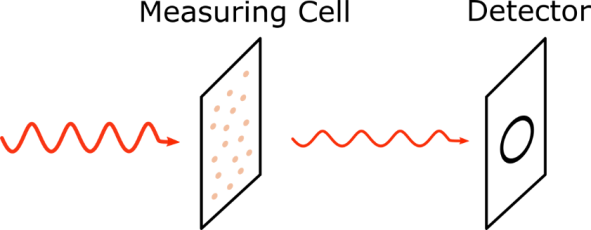

To perform a measurement, a Quantum Cascade Laser (QCL) is used due to its high power in the MIR region compared to other types of MIR-sources. It follows the following steps:

- Fresh cyclohexane is guided through the flow cell and a background value is recorded.

- The enriched cyclohexane is guided through the flow cell and its value is also recorded (see image below).

Based on the two values recorded for each measurement, an absorption value can be calculated and correlated to an oil concentration.

On-line Measurements:

During the Hydroptics project our aim is to completely automize the procedures mentioned above. A method for the continuous extraction, separation, and detection shall be developed and implemented in a user-friendly Hydroptics Prototype.

Issue:

Under normal circumstances, the ASTM D7678 standard, which demands measurement at a single wavelength, works very well. A clear phase separation between the water and the cyclohexane phase enables the user to perform multiple measurements without the need to take a background after each run. However, in certain cases it might be necessary to do so. This could be the case if the settling time is minimized to save time or if emulsions are formed. As a result, a slight spectrally flat drift behaviour could be observed due to the deposition of water or other absorbing substances in the measuring cell. For single measurements this is not an issue since fresh cyclohexane can be used, however for a completely automatic system, which requires recycling of the extraction solvent it would be advantageous to compensate for this effect.

Solution:

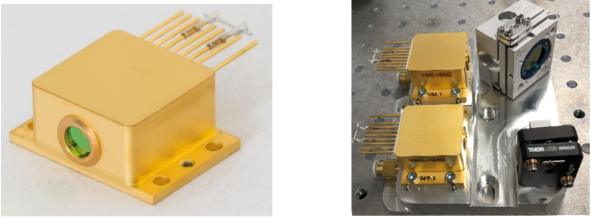

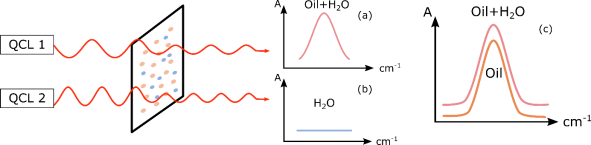

By using a dual-DFB QCL setup this drift behaviour can be compensated. Two laser beams at carefully selected wavelengths are guided through the measuring cell. The one laser emits radiation that is absorbed by both oil and water and the other in a region in which only water absorbs. Taking the difference in absorption values, one can derive the amount of absorption caused only by the water. Alpes Laser has developed such a dual-DFB QCL in one compact module (see image below on the right). It consists of two separate QCL’s each in an HHL housing whose beams are combined using a beam combiner.

Measuring in the range of 1370 – 1380 cm-1 provides us an absorption value of the oil and water (a), while the absorption at λ cm-1 (the precise wavenumber still needs to be optimized) provides us an absorption value caused only by the presence of water or other contaminating compounds (b). Together, the effective absorption caused only by the oil can be determined (c).

Link: https://hydroptics.eu/wp-content/uploads/2020/08/Press_release_14082020.pdf